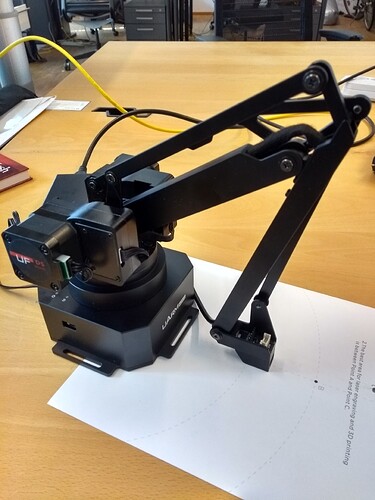

uArm Serial No.: C8FD19405647

Firmware Version: 3.1.9

Operation System: MacOS Sierra 10.12.5

uArm Controlling Method: Serial port direct commands

Hello, I’m using the communication protocol as specified in the Quick Start Guide to direct commands to my uArm Swift Pro. Is the P2242 command the reading of the absolute encoders for each joint ?

I don not understand why the uArm allows itself to go out of limits when the movement commanded takes it there. I mean, if there are absolute encoders that the firmware can read, then YOU (firmware programmers) can know when the next step for the motors affected by the movement will take them beyond mechanical limits and will produce the KLAK-KLAK noise and the uArm going nuts… I think there are a lot of users reporting that behaviour so, is this something you are going to fix in some future firmware versions ??

Please, do not misunderstand me… I love this robotic arm, its hardware is awesome and it performs pretty well and pretty stable… but the software provided, both firmware and desktop app are highly improvable.