@Shiv @Maximilian Does the extruder motor works properly? If the extension is connected correctly, there won’t any sound of clicking from the extruder and you can find out that the motor tries to push the PLA into the PEFT tube. The base extension is not a good design, it is neither aligh to left nor to right. It should be in the middle. If there is still any problem, please give me a video and I will try my best to help you. Thanks

hi, i think im having the same problem as you did. if you could, pictures of that would be great

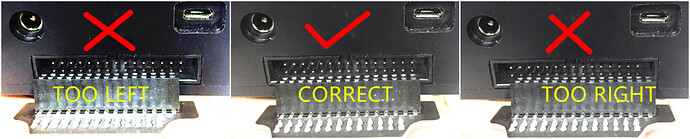

Ok now that’s a MUCH better picture. You may use this in the PDF instead of the current one for better explanation ![]()

I am currently doing the TOO LEFT version as that’s what I get from your official PDF.

Will try this weekend.

Already done, thanks for your feedback. ![]()

Sadly my connector is in the correct place. There is no sound of clicking, it will attempt to push, then seems to be jumping back when it cant anymore? I will have a fiddle tonight.

I found my issue, My apologies! somehow the pla had snapped inside the tube and was causing all kinds of issues, I was super gentle putting it in the second time and everything seems to be running!

thanks!

Hi, I thought I had the same problem as Shiv, my connector appears to be in the right place but the feeder jumps back every few seconds when it runs out of space to push into. I checked and it seems that the filament is reaching all the way to the extruder but it’s not getting through to the other side and printing. The extruder is heating all the way to 200 degrees, the feeder is pushing filament, and it is reaching the extruder but the filament stops at the extruder and won’t print. I tried handfeeding the filament to the extruder but when I pulled the filament back out it didn’t even look melted.

The filament might be stopped in somewhere in the tube, and it’s not reaching the hot end.

Could you please show us a video? That helps a lot

The videos were too big to upload here so I uploaded them to imgur - link: http://imgur.com/gallery/JFDXS

The filament is not getting stuck in the tube, as I showed in one of the videos, I even tried hand feeding the filament into the extruder without the tube and it still wouldn’t melt/go through.

It’s definitely reaching 200 degrees; I touched a piece of filament to the outside of it to check and it melted.

The filament is getting all the way to the extruder and getting stuck there somehow. Then, as the feeder keeps pushing filament in, the pressure builds up and the filament jumps back through the feeder.

this is exactly my situation.

i have the same problem and i made sure both ends were locked but it still didn’t work

The tubes are locked in for me too, still no luck.

@adam @nihar.patel628 please show us more details by a video (my email address: tony@ufactory.cc)? That would help us to find problem quickly! Thanks ![]()

Hi.

I’m having a similar problem. At step 4 of the manual, when I must keep feeding the PLA until it’s 60 mm out of the PTFE tube and go to step 5, where I must install the tube to the extruder, the PLA only enters for 40 mm and leaves 20 mm out.

I´ve tried to print nevertheless (taking back 20 mm of PLA) and see how the temperature reaches 200ºC and everything seems to be ok, but then I notice that no material comes out of the extruder and see that the feeding motor tries to push the PLA, but isn’t able to fulfill it’s task.

So the problem is that I’m not able to deed the extruder with 60 mm of material. I gets somewhere inside stuck. There’s something inside the extruder’s tube that doesn’t allow the PLA to reach the extruder’s head.

This is my first printing, so there shouldn’t be anything inside the extruder.

Ok now.

Found the solution. The PLA comes in a spool; that means that the very beginning of the PLA has a curved shape. So before inserting the first 60 mm in the extruder’s head, you must straighten these first 60 mm with your fingers and than carefully insert it in the extruder’s head. After a few tries it should get in place.

That’s it.

Good luck.

Thanks for your sharing, we did ignore this issue in the instructions. Will do it. Thanks for your feedback. Appreciate it!

Dam’s solution worked for me. Thanks a bunch!

I having issues that when i start the 3D print job, that the uArm doenst do anything. I had some messages going around to Lancer but i dont get any response anymore. The last thing he said was make a video and if necessary we will send you a new 3D print module. hopefully with feeder because i think that the the feeder stepper motor was dead on arival. But i dont have a way to test it. Does any one know a way how to test the feeder stepper motor?

Hi christian, I’ve sent the replacement in 11th Aug, the tracking number is:LX439902090CN, delivered by EMS, you can check it, thanks.